Sustainability

Towards a Sustainable Future

From the “Made in Italy” certification to technological innovation, from material research to partnerships with designers and universities, Calia Italia is a company oriented towards the future and committed to excellence. To this end, it has adopted a policy of continuous improvement aimed at ensuring increasingly sustainable production, pursuing a virtuous path of evolution that has characterized the company since 1965.

OUR CERTICATIONS

As proof of this commitment, Calia Italia holds certifications in compliance with the requirements of the Environmental Management System standard ISO 14001:2015 and the Quality Management System standard ISO 9001:2015.

The suppliers of the wood used for the structure of our products hold PEFC (Programme for the Endorsement of Forest Certification Schemes) and FSC (Forest Stewardship Council) sustainability certifications, ensuring that the wood originates from responsibly managed forests — from an ecological, economic, and social perspective. The FSC forest management standards include the protection of water quality, the prohibition of harvesting from ancient forests, the prevention of natural forest cover loss, and the ban on the use of highly toxic chemicals.

By purchasing an FSC-certified product, consumers contribute to the preservation of the world’s forests.

AUTOMATED LEATHER CUTTING AND AUTOMATIC HIDE SCANNING MACHINES

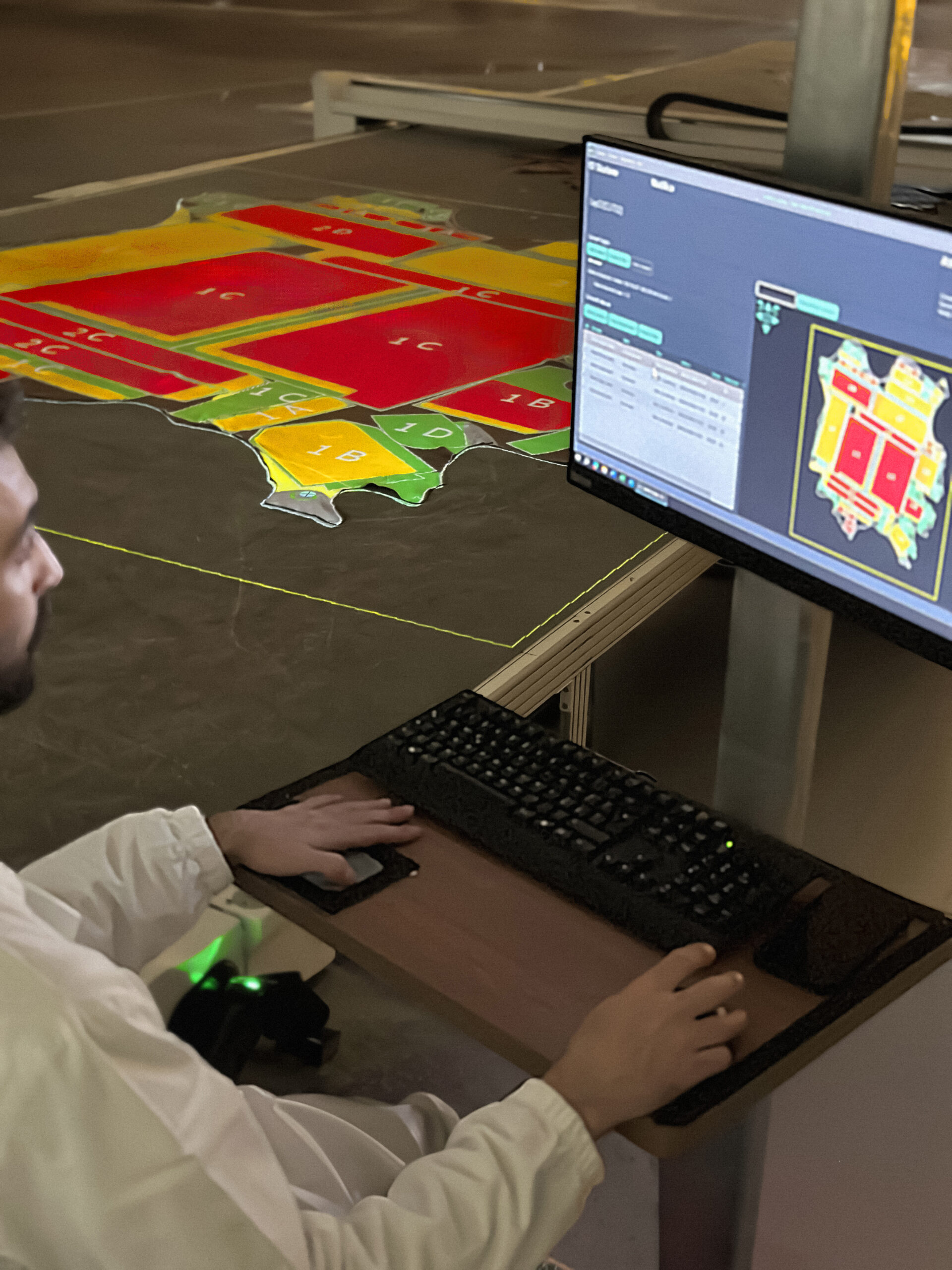

Since 2022, Calia Italia has been using high-performance machinery for the automated scanning and cutting of leather hides. This system integrates software and hardware (camera, video projector, PC, monitor) with cutting machines, ensuring greater efficiency and speed throughout the process.

After an initial inspection phase, the leathers are stored in the warehouse, with all information for each hide (batches, origin, quantities, and characteristics) entered into the database. Each hide is assigned a unique code, ensuring traceability and alignment with the corresponding customer order.

The hides are selected and scanned by an operator who marks any imperfections or defects, transmitting this information simultaneously to the software via a digital pen. The scanner employs augmented reality to read the hide and capture the defects indicated by the operator. This process enables the creation of a virtual warehouse that collects each digitized hide.

Based on this information, the server selects the most suitable hide and initiates the multi-hide automatic nesting process, which allows different model pieces to be cut from the same hide. Once the nesting process is completed, it is approved by the operator, who then prepares the hide for the cutting phase.

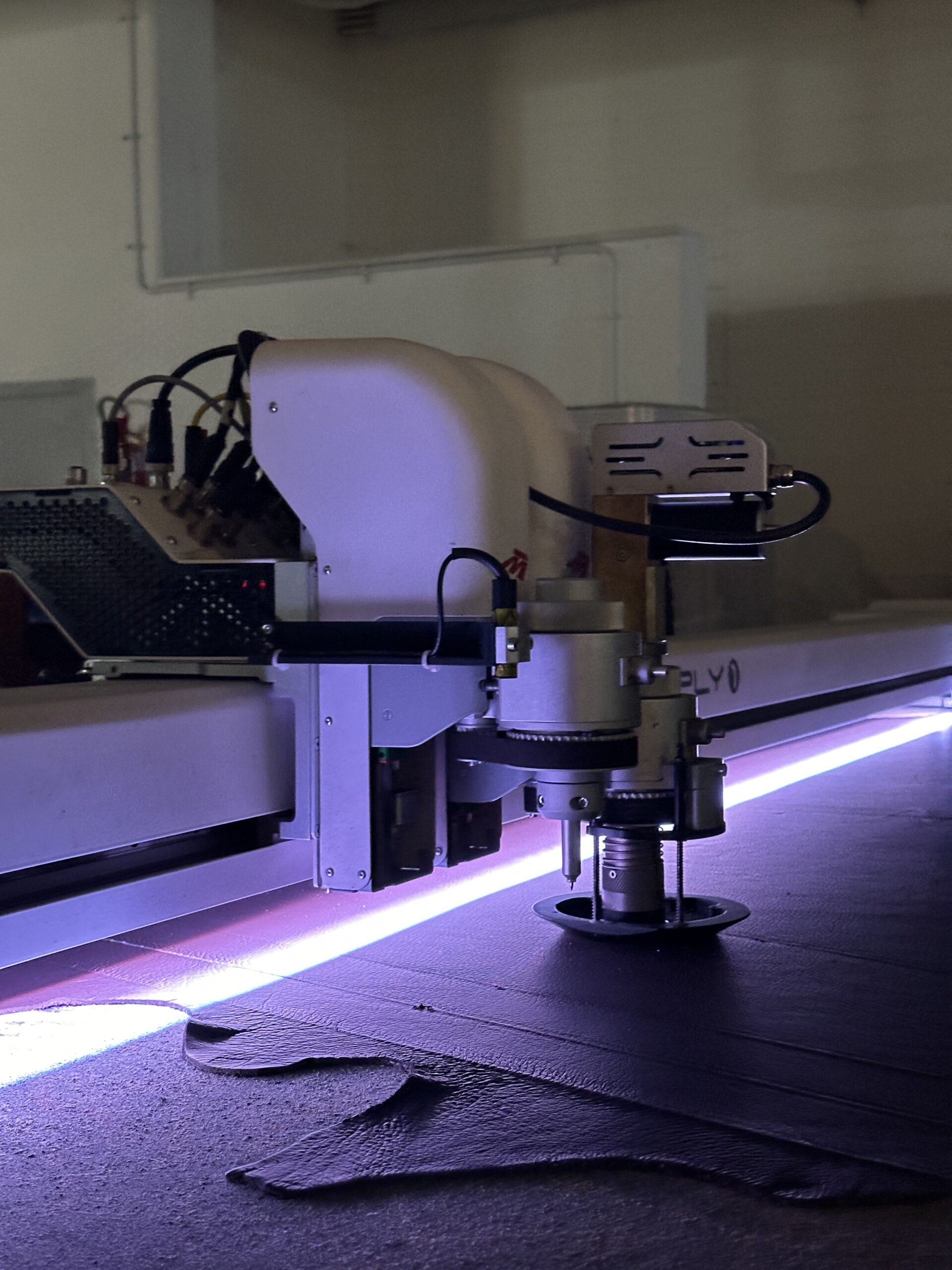

The leathers are processed individually and cut by a high-performance machine, ensuring both speed and precision. They are then collected, re-inspected, sorted, and packaged before being sent to the sewing department.

Benefits

- Material waste has been reduced by over 15%. Automated cutting allows for a fabric utilization rate of 90%, compared to a maximum of 75% with manual cutting.

- Hide scanning allows for precise warehouse monitoring and the creation of an unrivaled database. Every surface is mapped to the finest detail, including any defects on each hide. Using this extensive database, the software determines the optimal hide for the production of each model.

- While a traditional cutter could process 90–100 m² of leather per shift, the current system effortlessly handles 150 m².

- The introduction of machinery has not reduced the workforce – in fact, it has expanded it – while enabling employees to develop greater specialization and expertise.

- The workforce is protected and safeguarded, as employees are relieved from physically strenuous tasks such as manual cutting, which over time can cause tendon damage.

- Multiple models can be cut from a single hide, significantly reducing material waste. By contrast, manual cutting allows only one model per hide, resulting in higher levels of waste.

Green Energy and Efficiency: Calia Trade's Energy Sustainability

HEAT PUMP INSTALLATION

In 2022, the facility underwent a complete renovation of its cooling and heating systems.

Outdated gas boilers and non-eco-friendly air conditioning units have been replaced with advanced electric heat pumps, ensuring environmentally conscious heating and cooling.

PHOTOVOLTAIC SYSTEM

Since 2023, Calia Italia has been equipped with a 1,4 megawatt photovoltaic system, comprising a total of 6,100 m² of installed solar panels, with the goal of self-generating the green electricity required to make its facilities energy self-sufficient. Over the long term, the system is expected to reduce CO₂ emissions by approximately 90%.

CO₂ reduction achieved since the commissioning of the system to date: 1,239.56 tons.

Equivalent number of trees planted: 1,697.

Within the next three years, the plant’s capacity is expected to double, with the aim of significantly increasing renewable energy production and further reducing greenhouse gas emissions associated with the company’s energy consumption.

ENERGY EFFICIENCY IMPROVEMENT

In the cutting area, the thermal energy generated by the machine turbines is efficiently recovered and utilized to heat the facility through an advanced air intake and extraction system. During the winter months, the recovered warm air is redistributed throughout the surrounding spaces, optimizing energy consumption and minimizing environmental impact through an integrated heat recovery system.

By December 2025, all lighting fixtures are scheduled to be fully replaced with high-efficiency LED technology. This initiative aims to optimize electricity consumption, significantly reducing environmental impact by lowering CO₂ emissions associated with energy use. The adoption of LED lighting systems also enhances light quality and extends the lifespan of the fixtures, reducing maintenance costs and minimizing resource waste.

DISASSEMBLABLE PRODUCTS

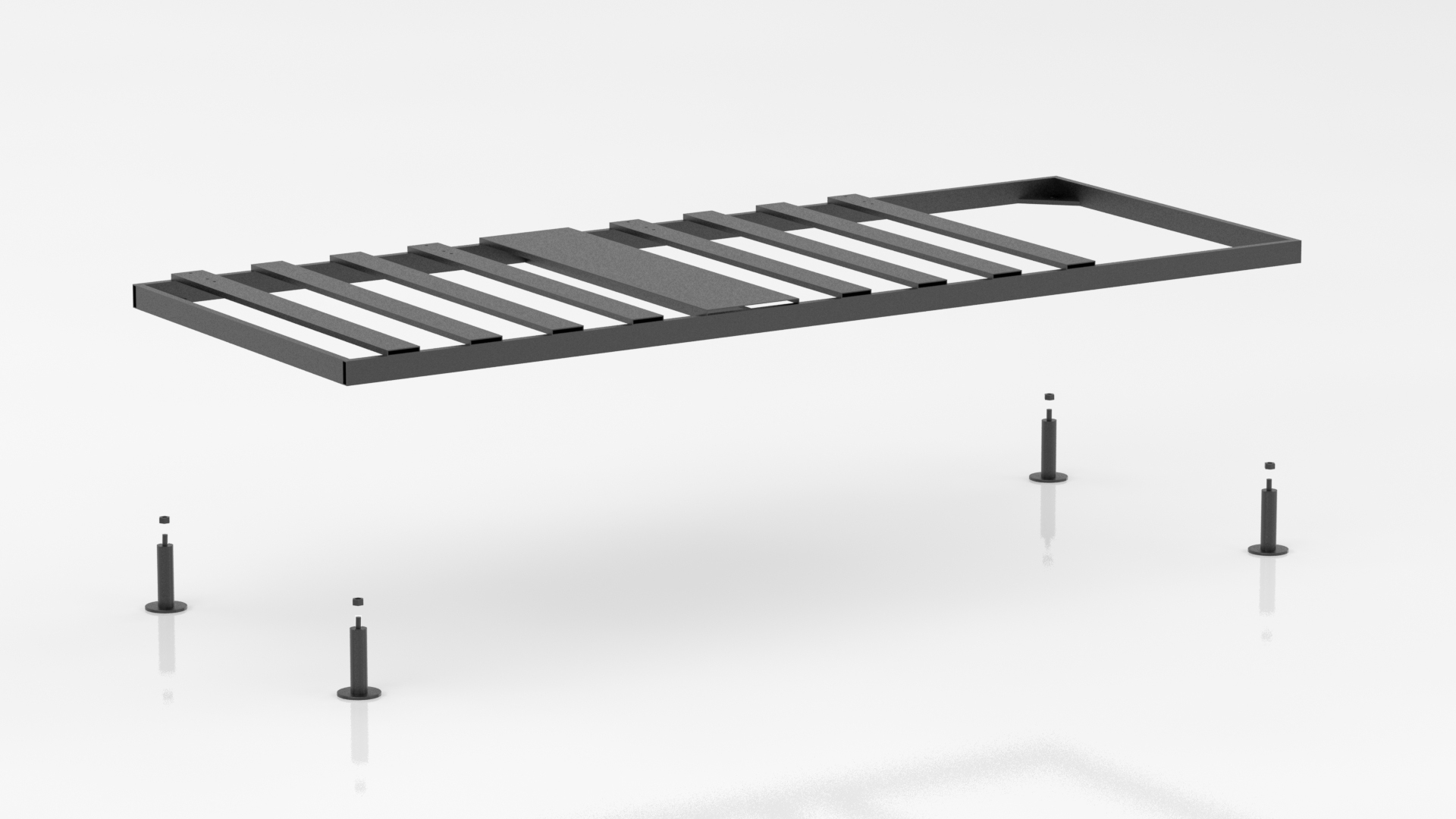

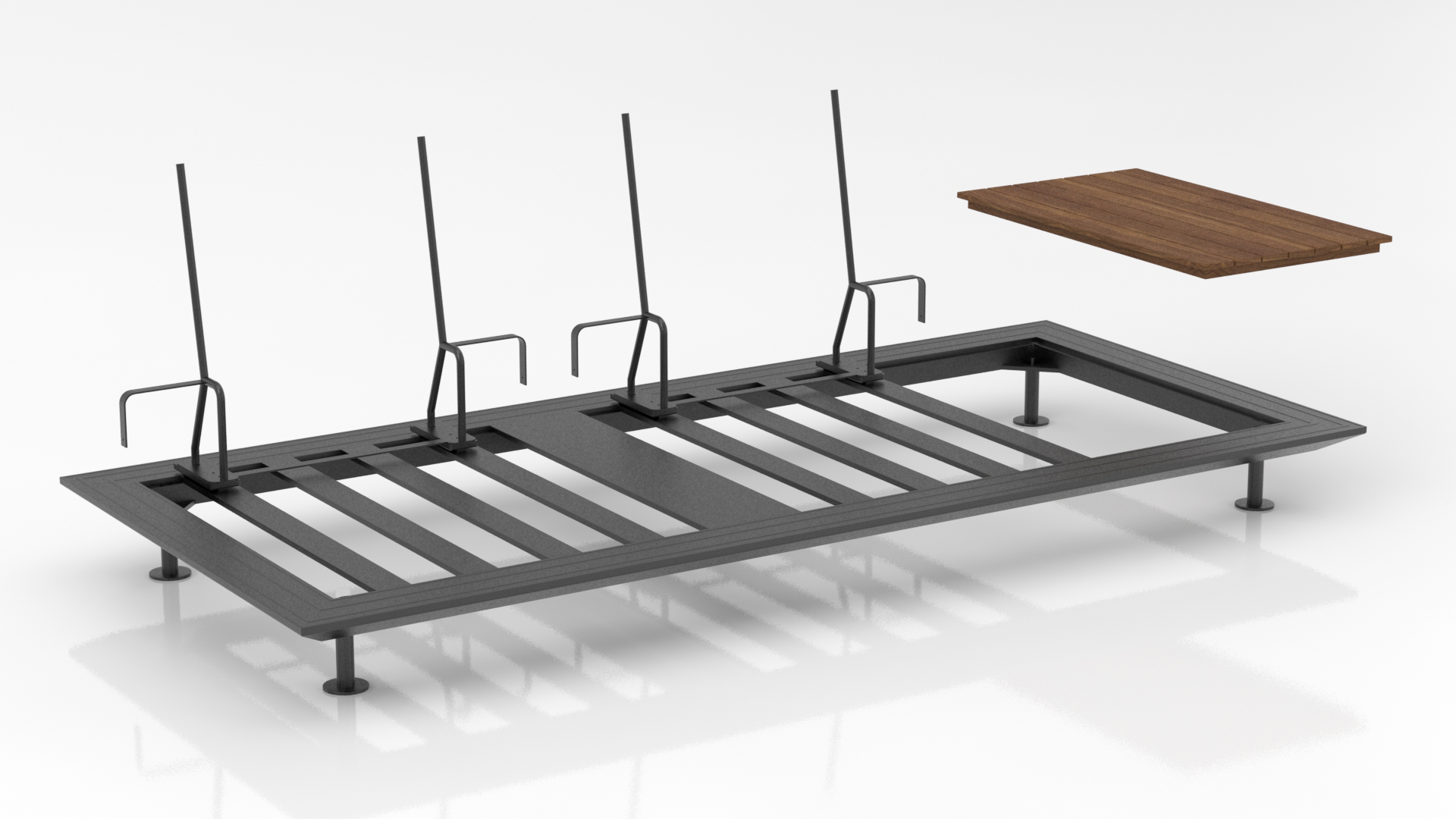

At the 2024 Salone del Mobile in Milan, Calia Italia unveils its first fully disassemblable model.

The Pralin Outdoor has been meticulously designed for outdoor living, incorporating rust-proof, mold-resistant, water-repellent, and breathable materials. It is also conceived according to sustainable design principles, with the ultimate goal of eliminating waste. Every single component is engineered for easy disassembly, allowing the piece to be conveniently stored during the winter months or, at the end of its life cycle, recycled to facilitate reintegration into the production process.

PRODUCTS MADE FROM WASTE MATERIAL

Among the products made from waste materials, the most iconic is undoubtedly the U’Strozz footstool. In the dialect of Matera, “U’Strozz” refers to rags. It is an eco-friendly footstool made of multiple layers of colored leather or fabric, derived from production scraps and held together by a book stool structure.

U’Strozz consistently reflects Calia Italia’s long-standing commitment to environmental issues—a respect deeply rooted in the company’s culture and origins. It also highlights the human resources involved in its production, elevating them from artisans to artists, as each product carries the unique imprint of its maker.

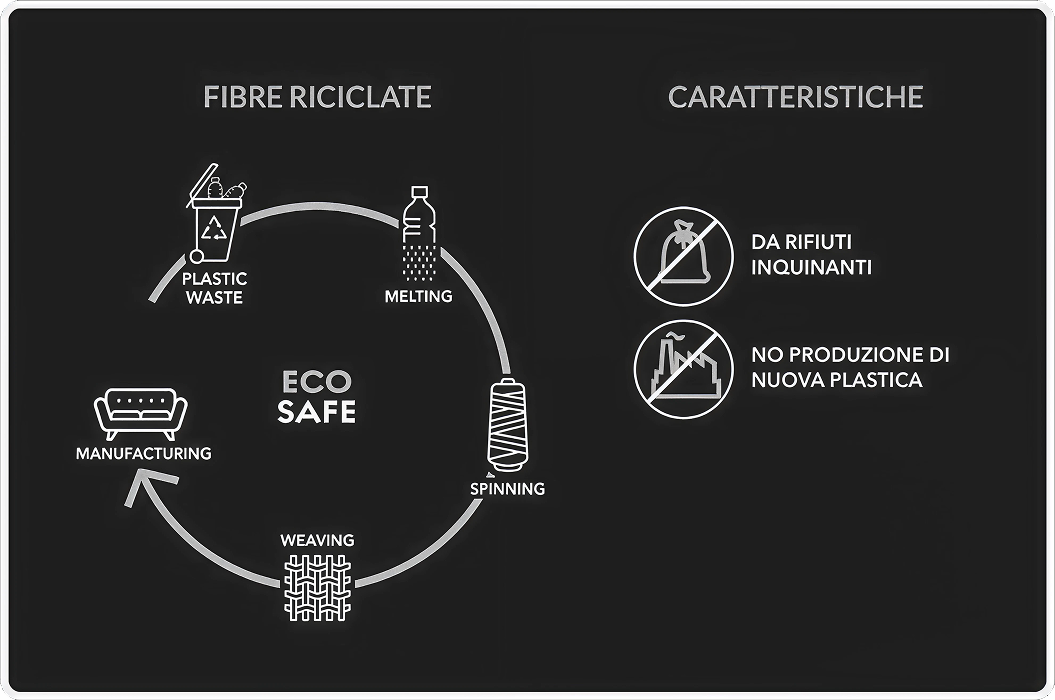

SUSTAINABLE COVERINGS

Calia Italia embraces green production by including ecological fabrics in its collection, certified under the Oeko-Tex Standard 100. This certification ensures that the products comply with environmental sustainability principles, following the “3Rs” approach: reduce, reuse, and recycle.

These coverings are made from recycled yarns derived from plastic waste and PET bottles that would otherwise end up in waste disposal sites. They are regenerated within a circular economy framework to create a sophisticated, next-generation yarn. The yarn contains no substances harmful to humans, and the production processes do not release toxic substances into groundwater. It is PFAS-free and additionally washable, stain-resistant, antibacterial, breathable, mold-resistant, UV-resistant, and rot-proof.